Guide to Buying Bearings

Do you feel uncertain about the bearings you ought to acquire? This guide will elucidate the essential terms and facts concerning bearings. We will also discuss which bearings are optimal for your particular style of riding or skating.

1. An Overview of Bearings

Two bearings are required for a wheel to revolve on the axle. A bearing can significantly affect the speed and sensation of your riding or skating.

Irrespective of your bearing type, you should avoid sand, water, and damp environments at all costs, as they greatly reduce the lifespan of your bearings. Cleaning and lubricating your bearings regularly can enhance their longevity and speed. View the cleaning process for bearings here.

Additionally, a spacer is necessary to fill the gap between the bearings to prevent damage and to ensure smooth rotation when the axles are secured. The spacer size is determined by the axle size utilised.

8 mm spacer

6 mm spacer

The calibre of bearings is defined by several factors, including:

- Material

- Precision (ABEC)

- Lubrication

- Sealed or open (Removable Shield)

Choosing the right bearing for you:

- If primarily riding or skating outdoors, we suggest sealed bearings lubricated with grease,

as they offer the best resistance to dirt and dust and necessitate minimal maintenance. - If mostly skating indoors, open bearings that spin rapidly and are easy to clean are suitable.

- If speed and long-distance runs are what you are after, then high precision bearings lubricated with oil are ideal. They spin exceptionally fast and are easy to clean, but dirt can harm them swiftly.

2. Installation

Typically, you can press a bearing with your thumbs. When correctly mounted, the bearing aligns with the wheel core or hub. If one corner protrudes, it is incorrectly mounted and will be damaged when skated on. For metal core wheels, mounting the bearing can be challenging; in such cases, use a rubber mallet or a square piece of wood for knocking it in.

Never use a metal hammer, as it will ruin the bearing and void your warranty.

Alternatively, lubrication may assist in seating a bearing; remove any excess lubrication afterwards.

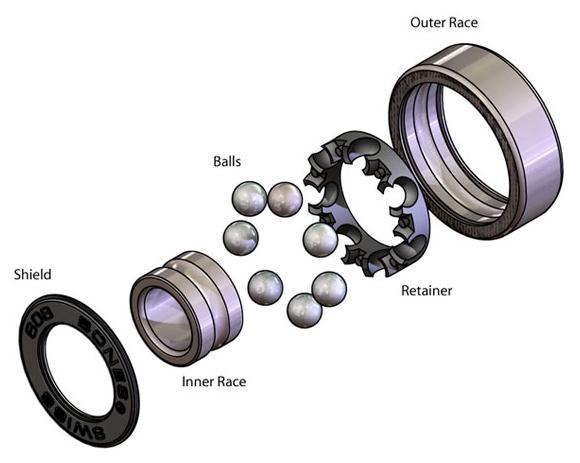

3. Delving into Bearings

Material

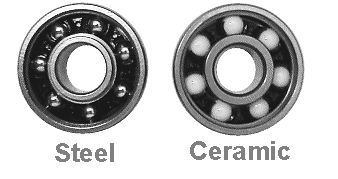

A bearing's material is critical for its quality and longevity. Most bearings are manufactured from steel. Low-cost bearings are generally made from pressed sheet metal or hardened carbon steel, neither of which is advisable for a long-lasting lifespan.

Superior bearings are crafted from genuine bearing-steel such as chrome, titanium, or Swiss steel.

In ceramic bearings (commonly utilised for speed skating), the balls are composed of industrial ceramic (Silicon Nitride). Ceramic balls resist rust and are more durable than steel.

The relationship between price and quality in bearings is quite direct, and reputable brands usually deliver reliable and durable bearings.

Precision/ABEC

The industry employs the ABEC specification to categorise bearings. ABEC indicates how well bearings can translate applied force. Higher ABEC ratings offer greater precision, efficiency, and speed capacities, although they do not necessarily increase rotational speed. The ABEC rating does not consider other critical elements like spacer and wheel precision or material. All bearings will degrade in precision with use.

Be aware that not all brands use the ABEC scale (e.g., Bones), and alternative scales for bearings do exist.

ABEC stands for Annular Bearing Engineering Committee.

Lubrication

Bearings can be lubricated with oil or grease. A bearing must never run out of lubrication, or it will melt, seize, or lose speed.

- Oil: Results in high speed due to reduced resistance. Thin oil facilitates greater speed but demands more frequent maintenance.

- Grease: Better resists water and dirt than regular oil. Requires minimal maintenance yet causes higher resistance, leading to reduced speed.

Note: Water can strip all lubrication! Once dry, the next usage will cause your bearings to heat excessively, possibly melting and making noise. Replacement is required. Sometimes if unused, they can be salvaged with proper cleaning and oiling before their next use.

Shields/Seal

To protect against dirt, sand, and water ingress, a shield or seal is often applied to one or both sides of the bearing.

- A Shield typically consists of a metal guard connected to the outer ring with slight spacing from the inner ring (also referred to as a dustproof bearing). Bearings with shields experience minimal friction, aiding speed but offer imperfect protection against water and dirt.

- A Seal (shown below) is made from steel-reinforced rubber, affixed to the outer ring, marginally touching the inner ring. It provides superior protection and negligible maintenance, albeit with increased friction and reduced speed.

4. Standards and Bearing Precision Demystified

ABEC ratings cover numerous factors, one being the eccentricity (roundness) of the inner ring track. The following table details the maximum allowed eccentricity.

| Type | mm | Inches |

| ABEC 1 | 0.0075 mm | (0.000295") |

| ABEC 3 | 0.0050 mm | (0.000197") |

| ABEC 5 | 0.0035 mm | (0.000138") |

| ABEC 7 | 0.0025 mm | (0.000098") |

| ABEC 9 | 0.0012 mm | (0.000047") |

This indicates that the higher the ABEC rating, the fewer deviations in the bearing elements = more energy is transferred to the wheel.

ABEC and ILQ are not directly equivalent since ILQ is a brand name while ABEC is a standard.

ABEC bearings are evaluated on production precision, not durability or function under load. Twincam, maker of ILQ, rates their bearings' quality on a scale similar to ABEC. However, ILQ bearings have 6 balls compared to the 7 in ABEC bearings.

For clarity, ILQ is not a standard like ABEC bearings. ILQ should therefore be seen as an unrated bearing from a professional inline bearing manufacturer and is not ideal for industrial machinery.

Bones bearings are crafted solely for skating - and are not comparable with ABEC specifications.

A glossary for bearings and their shields is provided below (bearing type is typically printed on the bearing along with the size, such as: 608ZZ).

608

- Standard bearing

- 22 mm outer diameter

- 7 mm width

- 8 mm inside diameter

688

- Mini/Micro bearing

- 16 mm outer diameter

- 5 mm width

- 8 mm inside diameter

Z

- Shield, 1 metal shield

- Open on one side for easy maintenance (always face the open side inward when mounting)

ZZ

- Shield, 2 metal shields

- The shields are held with a small C-ring that must be removed to take the shield off for maintenance.

2RS/RS/RZ

- Seal, 2 steel-armoured rubber seals

- Seals are mounted without C-rings. They can be removed carefully with a needle for maintenance.

BRS

- Seal, 2 steel-armoured rubber seals (contact-free)

- Seals mounted with no C-rings. Provides excellent protection from water ingress.