Purchasing Wheels for Scooters

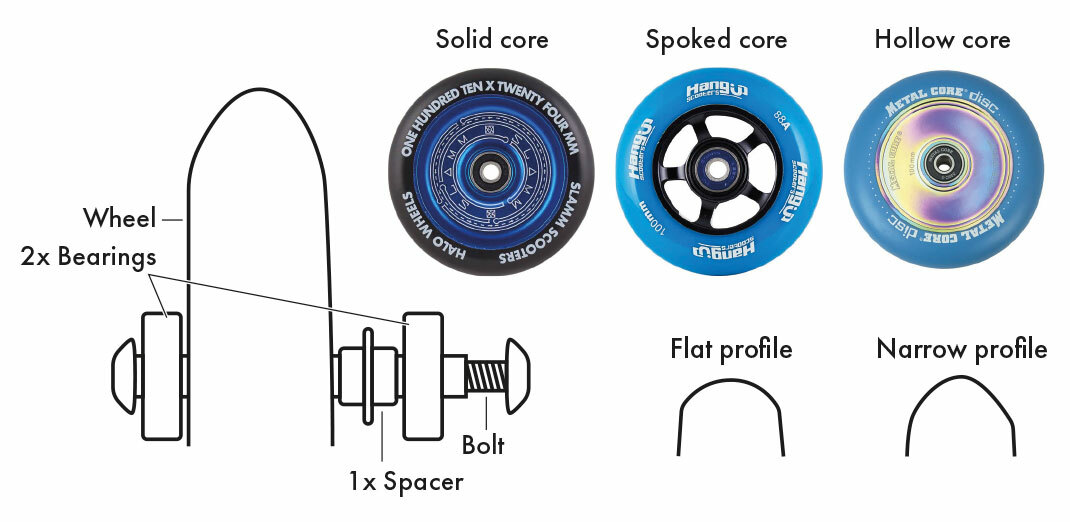

Each wheel requires two bearings and one spacer to work properly.

Wheels come in various materials, sizes, hardness levels, profiles, and core types.

The diagram illustrates the different components.

Cores

- Solid core. A robust core providing maximum strength.

- Spoked core. Features holes and cutouts, making the wheel lighter, yet less strong!

- Hollow core. The hollow interior allows for a lightweight option while maintaining strength. (Not as robust as the solid core)

- Plastic core, Image not shown. These don’t last long and offer some flexibility.

- Honeycomb core, Image not shown. Utilises the same idea as hollow cores but is lighter due to perforated holes.

Profiles

- Flat profile (provides strengthened rubber and maximum grip)

- Narrow profile (enhances speed)

Hardness

- The durometer scale ranges from 0-100a, with 100a being the hardest. Most scooter wheels are 85a.

- Hard wheels are more durable, slide more easily, and are faster!

- Soft wheels wear down faster but have excellent grip, making them ideal for parks and indoor environments.

- Sometimes, the hardness isn’t listed by manufacturers, so trial and error might be necessary.

Installing Bearings in the Wheel

- It can be challenging to fit bearings into a wheel, so we have a video guide for Installing bearings in a wheel with a metal core here.

Tips

- Ensure bearings are perfectly aligned with the centre during installation to prevent damage to both bearings and the wheel's centre.

- Using a hammer for wheel or bearing installation will void the warranty and the right to claim a replacement.

- Wheels with a flat profile might not fit in forks designed for pointed profiles.

- Replace worn wheels to ensure safety and to avoid damaging the Flex fender brake!

Claim or Wear and Tear?

Wheels designed for performing tricks are subject to intense stress and, like all wheels, have a limited lifespan.

Each time you attempt tricks like a tail whip or a 360, landing sideways places a lot of stress on the wheels. Repetitive actions can lead to wheel material breaking or pieces being torn off.

How do you decide if it’s a claim issue or just wear from use?

Flat spots

Excessively hard braking that locks the wheel against the tarmac can cause "flat spots." This results in a flat line on the wheel that causes uneven riding.

A "flat spot" does not result from a production issue and is not covered by standard warranty. It results from improper use, as no wheel is harder than tarmac.

Dehub

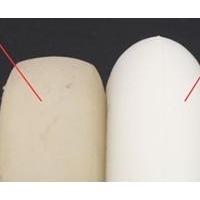

Below is an image of two wheels. The left one, still relatively new, shows less than 30% wear, while the right one is completely new.

If a wheel appears almost new with less than 30% wear, and the urethane has visibly come away from the hub, it might indicate a manufacturing fault as shown below:

When a wheel experiences more than 40% wear and the urethane is torn off or broken but remains attached to the hub, it is typically not a manufacturing fault.

If you suspect a manufacturing flaw with your product, refer to our claim guide to understand the necessary information to initiate a claim.

Return to Assembling a custom trick scooter

Return to Stunt Scooters: An Explanation