Guide to Purchasing Scooter Forks

Prepare yourself with our in-depth guide on selecting the ideal stunt scooter forks. We will explore crucial considerations before choosing a new freestyle scooter fork, focusing on compatibility, wheel dimensions, wheel offset, and additional factors.

A precisely tuned stunt scooter requires an exceptional fork. The fork supports the front wheel of your scooter, and it defines the wheel sizes you can fit – concerning both width and diameter. Look forward to some valuable tips on stunt scooter forks!

Overview

Understanding Scooter Fork Basics

The fork runs through the headset and the headtube on your deck. It mounts the front wheel, and the compression system, clamps, and bars are attached atop the fork. Your fork plays a substantial role in your complete setup since it dictates the wheel sizes that can be installed on your scooter.

Today, the majority of scooter forks are crafted from a single piece of aluminium, enhanced with various heat treatments. Previously prevalent, the outdated threaded steel scooter forks are now obsolete due to their lesser durability and heavier weight.

Scooter forks compatible with SCS, HIC, and IHC feature an integrated starnut within the fork tube, allowing the compression bolt to fasten into it during compression system installation.

ICS arrangements differ because they place the starnut inside the bar, while the compression bolt is fitted from underneath the fork before the wheel's installation. If uncertainty about your compression system arises, reviewing our all-encompassing guide is recommended:

When selecting a new front fork for your scooter, key considerations include weight, wheel sizing, wheel offset, and compression type. This guide aims to delve deeper into these essentials.

We routinely carry top-tier scooter forks from industry-leading manufacturers, and there's likely one tailored to your preferences. Should you decide to make a purchase, we invite you to explore our collection of high-quality forks for stunt scooters:

Scooter Forks: Wheels and Sizing

When selecting a new fork for your scooter, always verify its compatibility with your wheels. Match the wheels by diameter and width, ensuring that the wheel diameter does not surpass the maximum specified by the fork, and that the wheel hub's width is equal to or smaller than the fork’s indicated wheel size.

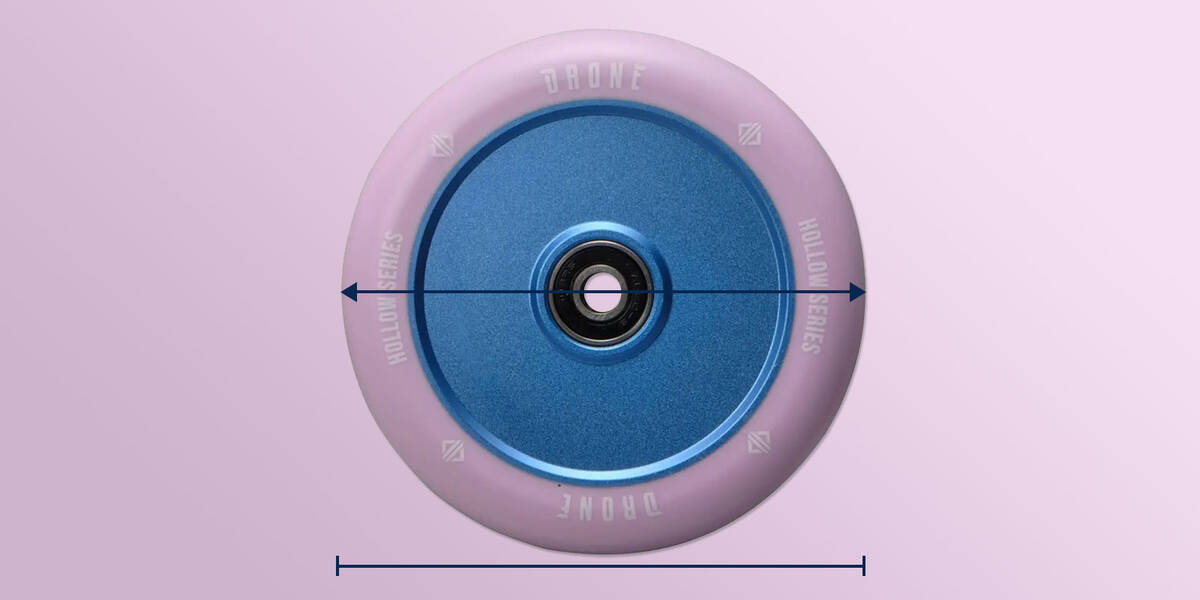

Wheel Diameter

Most scooter forks accommodate wheel diameters of 110 mm, the most frequent size. Nonetheless, numerous forks can fit scooter wheels up to 125 mm. Simply avoid using wheels that surpass the fork's limits, and everything should work seamlessly.

For instance, if opting for wheels with a diameter of 115 mm, ensuring your fork can handle such or larger sizes is crucial.

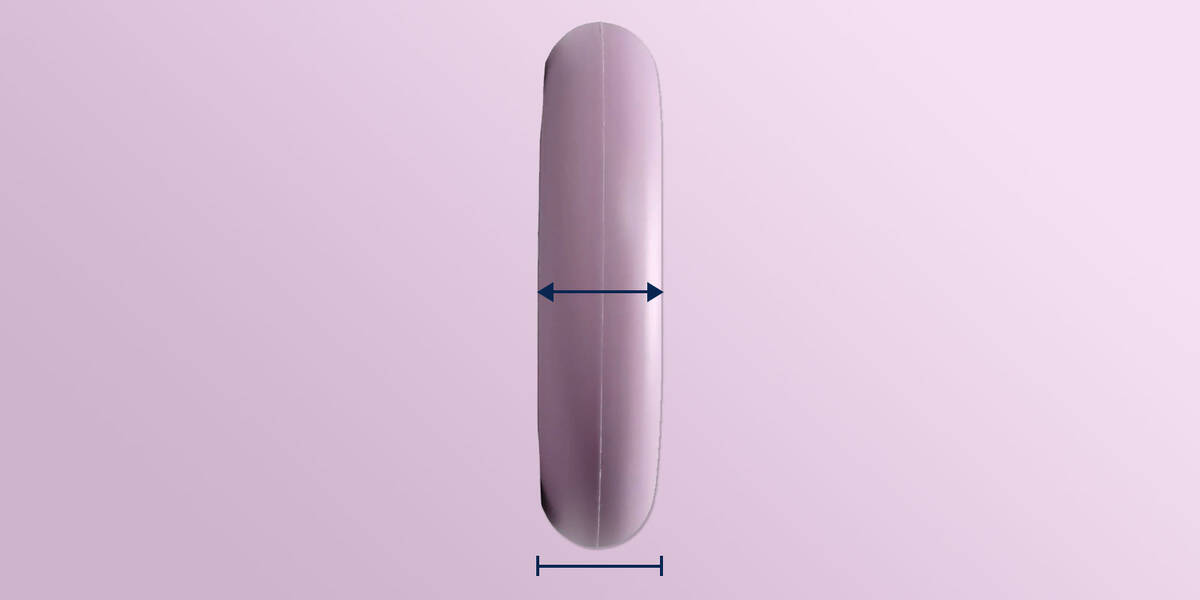

Wheel Core Width

Scooter forks are engineered for specific wheel widths, generally between 24 to 30 mm. Among these, widths of 26 and 28 mm are common scooter wheel sizes.

Scooter forks often include spacers so a fork accommodating wheels up to 30 mm can also fit 24, 26, and 28 mm wheels when equipped with appropriate spacers.

While narrower wheels can be installed on forks designed for wider hub widths, a wheel wider than the fork's capacity, such as a 30 mm wheel on a 24 mm fork, will not fit.

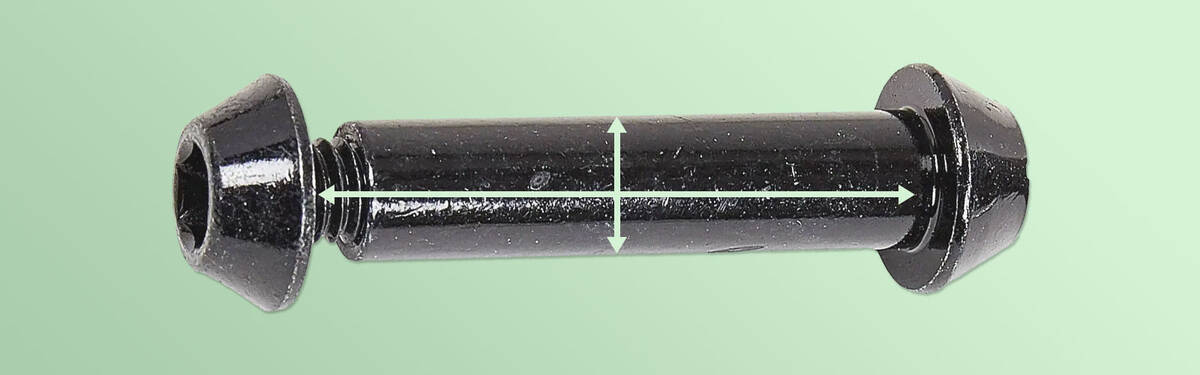

Fork Axle Diameter and Length

The common wheel axles for scooters typically have a diameter of 8 mm, while some forks also accommodate axles with a 12 mm diameter. The typical bearing size in scooters is 608, necessitating an 8 mm compatible axle. Forks compatible with the 12 standard frequently come with 8 mm adapters, allowing you to use the standard 8 mm axles as well.

The suitable axle length is determined by your scooter fork’s width from the outside, needing to be equal or longer than it.

The Concept of a 12 Standard Scooter Fork

12STD scooter forks are intended for wheel axles with a 12 mm diameter. For this axle size, bearings of size 6001 are necessary.

A pro scooter setup with a 12-standard normally comes with larger and wider wheels. Typically, such setups deliver better speed, stability, and durability, though they tend to be heavier and less nimble.

Many 12 standard forks include spacers enabling the fitment of 8 mm axles and typical 608 bearings on the fork.

Transitioning to a 12STD system requires awareness that alongside the 12STD fork, you'll need wheels to accommodate 6001 bearings and a deck allowing for larger wheels and axles. Our selection is at your disposal:

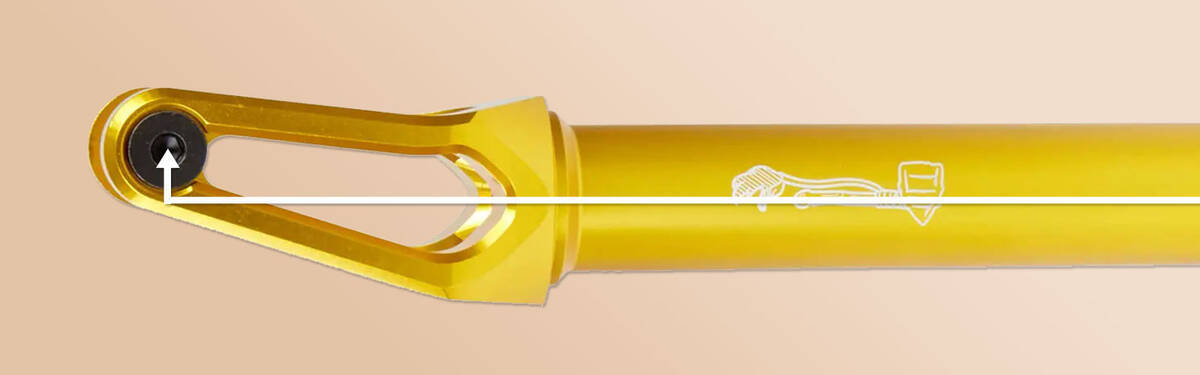

Wheel Offset in Stunt Scooter Forks

Wheel offset is a measure in millimetres indicating the distance from the fork's turning centre to the wheel axle. Often called the rake, it illustrates how far the wheel is positioned ahead of the fork.

Wheel offset greatly impacts your scooter's stability and manoeuvrability, affecting the wheelbase (the span between front and back wheels).

A 10 mm wheel offset is prevalent. It elevates stability and control, aiding in making your scooter's steering more effortless and predictable.

Zero-offset forks offer exceptional agility and responsiveness. With zero offset, the front wheel is closer to the user, facilitating manoeuvrability and responsiveness. Performing nose manuals is simplified due to the foot's proximity to the ground. Similarly, executing foot jams becomes easier as a more significant wheel segment is accessible for jamming.

Scooter Forks and Compression Protocols

Forks for SCS and HIC compressions share similarities. A starnut within the fork tube permits a compression bolt to secure in place. The contrast lies in their compression adjuncts: SCS utilises an SCS clamp, whilst HIC relies on an HIC shim.

IHC compression forks have an especially narrow fork tube, optimal for those who seek to lessen the aggregate weight of their setup. Thus, IHC forks are typically the lightest amongst scooter forks.

- SCS Scooter Forks: Compatible with both standard and oversized bars lacking slits, and fitting either oversized or standard SCS clamps

- HIC Scooter Forks: Suitable for oversized bars with slits and oversized non-SCS clamps

- IHC Scooter Forks: Designed for standard-sized bars and standard, non-SCS clamps

ICS and ICS-10 forks have their compression bolts installed from the fork's base, threading into a starnut situated within the bars. Even though ICS systems are rare in custom setups, they are known for their remarkable lightness compared to other compression systems.

Should you face uncertainty about fork and component compatibility, these resources may provide clarity: